What do students really need to prepare for success in a workforce that is changing crazy fast? Work-Based Learning (WBL) is right at the top of that list. But school leaders often tell us that transportation and school schedules make it very difficult for them to get kids to businesses for activities such as internships, mentoring, and pre-apprenticeships. While these activities are great, WBL is so much more! Recently, our team had a great opportunity to visit the Amatrol factory in Jefferson Indiana, and learned how they are leading the way in increasing access to WBL through their simulated work-based learning experiences (and industry-recognized credentials, too!),

Work-based learning is defined as sustained interactions with industry or community professionals in real workplace settings, or simulated environments at an educational institution, that foster in-depth, firsthand engagement with the tasks required in a given career field, aligned to curriculum and instruction.

Carl D. Perkins Career and Technical Education Act definition of work-based learning.

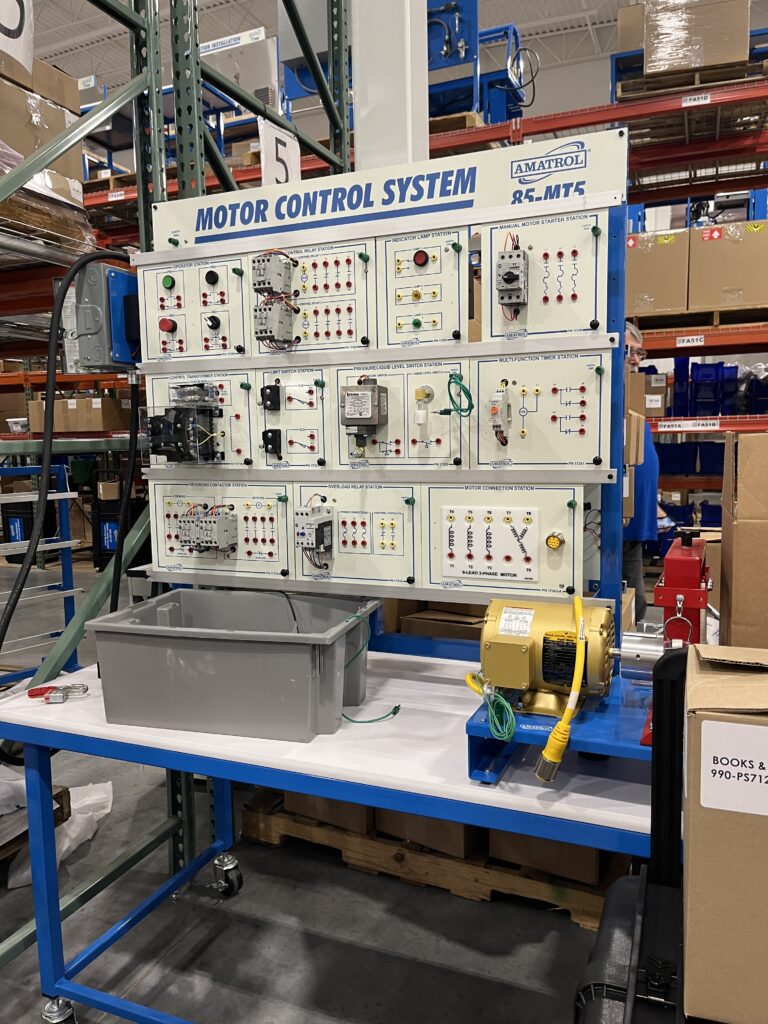

During our visit we discovered that Amatrol designs and manufactures amazing learning systems that build students’ knowledge and skills in a wide variety of in-demand career fields including logistics, advanced manufacturing, skilled trades, robotics, computer science, solar and wind energy, mechanical maintenance, engineering, agritech and much more. Each learning system was designed in collaboration with industry partners so the curriculum and hands-on learning are always exactly what businesses need. These learning systems are also used by many industries themselves to train their own new workers.

Amatrol’s High School programs use a unique blend of project-based team learning combined with a rotational individualized learning format for technical skills development. Depending upon school needs, the curriculum can include equipment based labs as well as virtual labs. While designed for self-paced learning, Amatrol’s learning programs are equally effective in traditional classroom settings. All of Amatrol’s learning programs allow students to fully experience the rewards of hands-on, applied technical learning. The high school programs also articulate to colleges for up to 18 credit hours!

We also learned that Amatrol’s version of an advanced manufacturing factory is so much different than our perception. We saw a great balance between humans working on creating and assembling products and technology based solutions that include robotics and artificial intelligence to increase efficiency. One thing that stood out most to me was that the factory felt more like a collaborative studio than a production line. Each employee was extremely friendly and held a strong sense of pride and craftsmanship in their work. This environment mirrors what we should aim to create in educational settings, spaces where students can build their unique skills and talents, work together, and take pride in their work.

Of course, we know that these products come with a cost. If you are interested in getting support from our grant gurus to find and write grants for you to get your hands on these products, let’s talk!

If you want to learn about how Amatrol products might help you build out high quality work-based learning programs, Kelley ([email protected]) can get you connected. They will also be present and ready to support you at our Cybersecurity Design Lab this November! Register your team for free before spots fill up!